Femtosecond Lasers Solve Describe voltaic Panels’ Recycling Project

Describe voltaic panels are built to final 25 years or more in all forms of climate. Key to this longevity is a staunch seal of the photovoltaic materials. Manufacturers fabricate the seal by laminating a panel’s silicon cells with polymer sheets between glass panes. Nonetheless the sticky polymer is exhausting to vary into self reliant from the silicon cells at the tip of a photo voltaic panel’s existence, making recycling the materials more complicated.

Researchers at the U.S. Nationwide Renewable Vitality Lab (NREL) in Golden, Colorado dispute they’ve stumbled on a greater come to seal photo voltaic modules. The exhaust of a femtosecond laser, the researchers welded collectively photo voltaic panel glass with out the usage of polymers equivalent to ethylene vinyl acetate. These glass-to-glass precision welds are real ample for outdoor photo voltaic panels, and are better at keeping out corrosive moisture, the researchers dispute.

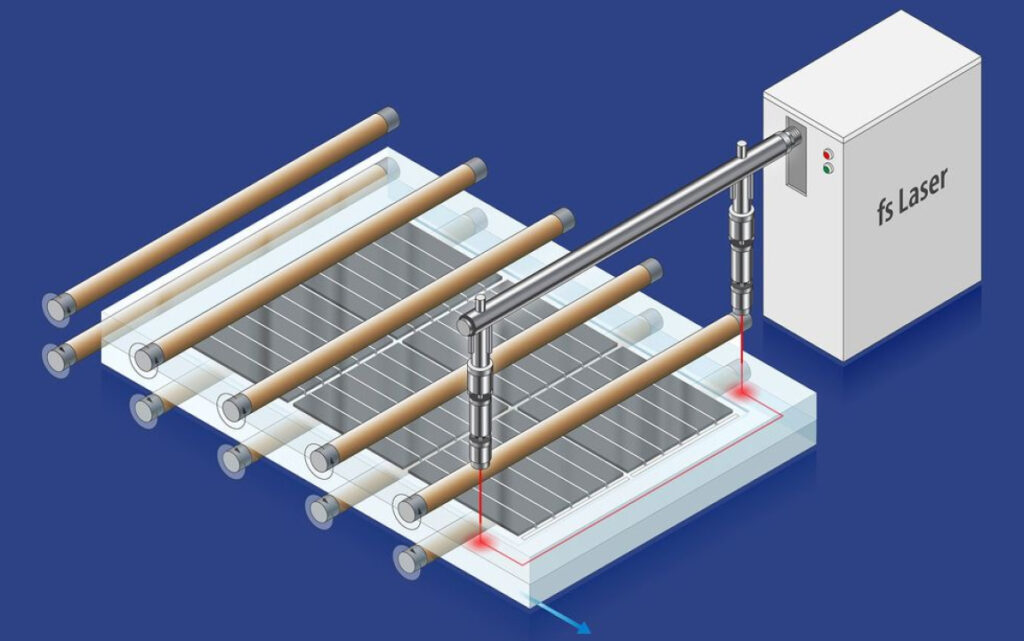

A femtosecond laser welds a small half of test glass.NREL

A femtosecond laser welds a small half of test glass.NREL

“Describe voltaic panels are not with out reveal recycled,” says David Youngera senior scientist at NREL. “There are companies which would possibly possibly well be doing it now, however it’s a mighty play between model and again, and a variety of the reveal is with the polymers.” And not utilizing a adhesive polymers alive to, recycling facilities can more with out reveal separate and reuse the treasured materials in photo voltaic panels equivalent to silicon, silver, copper, and glass.

As a consequence of the polymer reveal, many recycling facilities merely trash the polymer-covered silicon cells, and only salvage neatly the aluminum frames and glass encasements, says Silvana Ovaitta photovoltaic (PV) analyst at NREL. This partial recycling wastes basically the most treasured materials within the modules.

“At some level there’s going to be an huge amount of spent panels accessible, and we desire to salvage it staunch, and compose it easy to recycle.” —David Younger, NREL

Discovering model-effective recommendations to recycle your entire materials in photo voltaic panels will change into increasingly indispensable. Manufacturers globally are deploying ample photo voltaic panels to provide an extra 240 gigawatts every twelve months. That fee is projected to amplify to some terawatts by 2030, Ovaitt says. By 2050, anyplace from 54 to 160 million tonnes of PV panels would possibly possibly well relish reached the tip of their lifespans, she says.

“At some level there’s going to be an huge amount of spent panels accessible, and we desire to salvage it staunch, and compose it easy to recycle. There’s no reason now to not,” says Younger. A replace in manufacturing would possibly possibly well aid alleviate the reveal—though not for a minimal of 1 other 25 years, when panels constructed with the novel methodology would be due to the be retired.

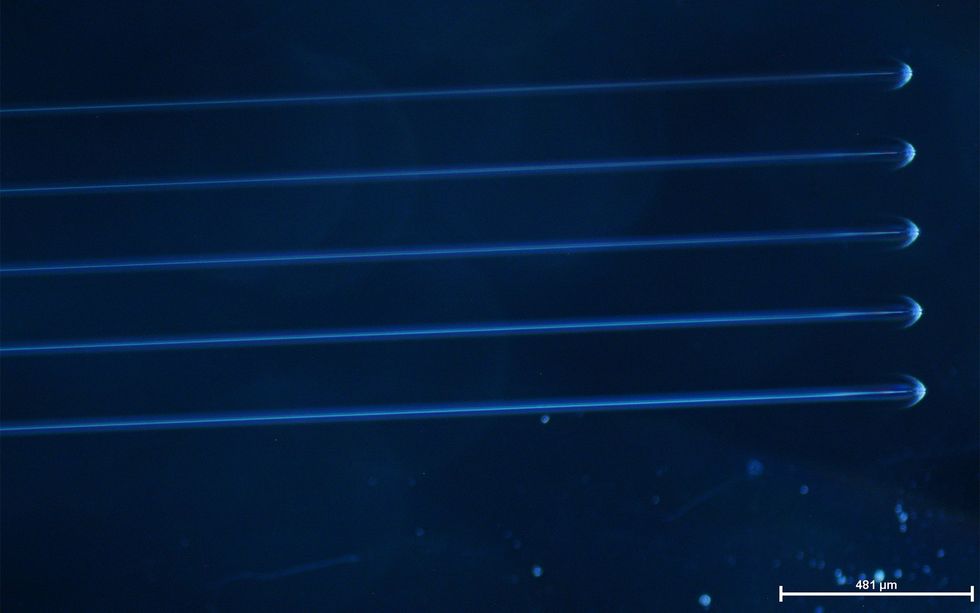

In NREL’s methodology, the glass that encases the photo voltaic cells in a PV panel is welded collectively by precision melting. The precision melting is achieved with femtosecond lasers, which pack a tall form of photons correct into a truly instant time scale–about one millionth of 1 billionth of a 2nd. The form of photons emitted per 2nd from the laser is so intense that it changes the optical absorption activity within the glass, says Younger. The activity changes from linear (regular absorption) to nonlinear, which permits the glass to soak up vitality from the photons that it would on the total not soak up, he says.

The intense beam, centered come the interface of the two sheets of glass, generates a small plasma of ionized glass atoms. This plasma permits the glass to soak up most of the photons from the laser and within the community melt the two glass sheets to create a weld. Because there would possibly possibly be not an commence floor, there would possibly possibly be not this kind of thing as a evaporation of the molten glass for the duration of the welding activity. The dearth of evaporation from the molten pool permits the glass to chill in a stress-free thunder, leaving a truly real weld.

A femtosecond laser creates precision welds between two glass plates.David Younger/NREL

A femtosecond laser creates precision welds between two glass plates.David Younger/NREL

In stress exams performed by the NREL neighborhood, the welds proved nearly as real as the glass itself, as if there became once no weld in any admire. Younger and his colleagues described their proof-of-theory methodology in a paper printed 21 February within the IEEE Journal of Photovoltaics.

Here’s the principle time a femtosecond laser has been outmoded to test glass-to-glass welds for photo voltaic modules, the authors dispute. The price of such lasers has declined over the last few years, so researchers are discovering uses for them in a extensive vary of functions. As an illustration, femtosecond lasers had been outmoded to make 3D mid-air plasma displays and to flip tellurite glass correct into a semiconductor crystal. They’ve additionally been outmoded to weld glass in scientific devices.

Earlier than femtosecond lasers, study groups attempted to weld photo voltaic panel glass with nanosecond lasers. Nonetheless those lasers, with pulses a million cases as long as those of a femtosecond laser, couldn’t make a glass-to-glass weld. Researchers tried utilizing a filler cloth known as glass frit within the weld, however the bonds of the dissimilar materials proved too brittle and used for outdoor photo voltaic panel designs, Younger says.

Besides to making recycling easier, NREL’s make would possibly possibly well also merely compose photo voltaic panels final longer. Polymers are heart-broken barriers to moisture when compared with glass, and the material degrades over time. This lets moisture into the photo voltaic cells, and at final leads to corrosion. “Present photo voltaic modules aren’t water tight,” says Younger. That can be an field for perovskite cells, a number one next-generation photo voltaic technology that is extraordinarily sensitive to moisture and oxygen.

“If we are in a position to provide a particular more or less seal the set we are in a position to salvage rid of the polymers, not only pause we salvage a greater module that lasts longer, however additionally individual who’s much easier to recycle,” says Younger.